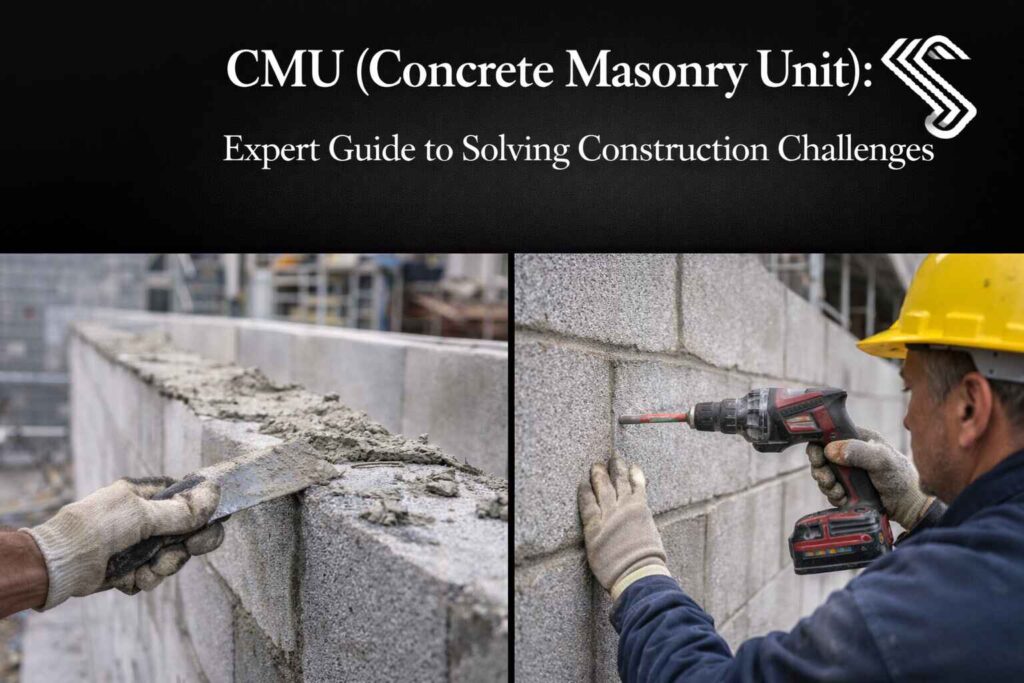

At our core, we believe that knowing your building materials is the first step toward a great project. A CMU (Concrete Masonry Unit) is the main strength behind most modern buildings. To put it simply, a CMU is a standard rectangular block made from cast concrete. It uses a mix of Portland cement and small stones or sand. It is much more than a plain gray block. It is a flexible building tool used for everything from strong home foundations to large walls that hold up heavy roofs.

Many people in the building world still use the term “cinder block” by mistake. We want to make sure our customers know that there is a big difference between the two. Modern Concrete Masonry Units are much heavier and stronger than the old ash blocks used in the past. Using the right name and the right parts is the best way to keep your building safe. We want to help you prevent any structural problems or costly repairs before they even start.

In this easy guide, we will show you all the facts about CMU sizes, costs, and the different types you can buy. Whether you are working on a small backyard project or a large office building, our goal is to give you clear answers. Let’s look at the standard sizes and features together. This will help you finish your construction project with high confidence and professional results.

What Does CMU Stand For in Construction?

The acronym CMU stands for Concrete Masonry Unit. While it may sound technical, it simply refers to a precast concrete block used in masonry construction. Unlike poured-in-place concrete, which requires temporary wooden forms, a CMU is manufactured in a factory under controlled conditions and delivered to the job site ready for installation.

In the world of structural engineering, these units are categorized by their weight and compressive strength. In 2026, the industry has moved toward high-performance units that offer better thermal resistance and lower carbon footprints. When you choose a CMU, you aren’t just buying a “block”; you are selecting a precision-engineered component designed to meet strict ASTM International standards.

Understanding CMU Composition and Characteristics: The Science of Strength

To solve common issues like wall cracking or moisture penetration, you must understand what goes into a Concrete Masonry Unit. A high-quality CMU is defined by its precise chemical and physical makeup.

The Material Mix

- Portland Cement: The “glue” that holds everything together.

- Aggregates: Stones and sand that provide bulk and strength.

- Water: Used for hydration, kept at low levels to maintain the block’s shape.

- Admixtures: Extra ingredients that repel water or add color.

Key Density Classes (ASTM C90)

- Lightweight: Best for insulation and fire resistance; easier for workers to lift.

- Medium Weight: The standard choice for most homes and offices.

- Normal Weight: The densest option; best for blocking sound and heavy loads.

Key Performance Characteristics

- Compressive Strength: Measured in PSI (pounds per square inch). Standard load-bearing units typically range from 1,900 to 3,000 PSI, though custom mixes can go much higher.

- Water Absorption: This characteristic dictates how much moisture a block can soak up. Lower absorption rates are critical for preventing “freeze-thaw” damage in colder climates.

- Dimensional Stability: Because they are pre-cured, CMUs exhibit minimal shrinkage compared to poured concrete, which helps prevent structural shifts after the wall is built.

Standard Concrete Masonry Unit Sizes and Dimensions: What You Need to Know

One of the most common mistakes in construction planning is confusing nominal dimensions with actual dimensions. To ensure your project measurements are perfect, you must understand how these blocks are sized.

What is the difference between Nominal and Actual size?

In the masonry world, we use a 3/8-inch mortar joint.

- Nominal Size: The size used for naming (e.g., 8x8x16).

- Actual Size: The physical size of the block (e.g., 7 5/8″ x 7 5/8″ x 15 5/8″).

When you lay the block with a layer of mortar, the total space it occupies equals the nominal size. This makes calculating the number of blocks needed for a wall much easier.

Standard CMU Dimensions Chart

| Nominal Size (W x H x L) | Actual Dimensions | Common Industry Usage |

| 4″ x 8″ x 16″ | 3 5/8″ x 7 5/8″ x 15 5/8″ | Interior partitions, veneers |

| 6″ x 8″ x 16″ | 5 5/8″ x 7 5/8″ x 15 5/8″ | Small residential retaining walls |

| 8″ x 8″ x 16″ | 7 5/8″ x 7 5/8″ x 15 5/8″ | Standard structural walls |

| 12″ x 8″ x 16″ | 11 5/8″ x 7 5/8″ x 15 5/8″ | Heavy-duty foundations |

Types of Concrete Masonry Units and Their Uses

Not all CMUs are created equal. Depending on your building’s needs, you will choose between various configurations.

1. Hollow vs. Solid CMU

- Hollow Units: These are the most common. They feature “cores” or cells that allow for vertical reinforcement (rebar) and grout. They are lighter and offer better space for running electrical conduits.

- Solid Units: These blocks have no large cores. They are used for heavy load-bearing points, capping the top of a wall, or in areas where maximum fire protection and sound dampening are required.

2. Architectural and Decorative Blocks

To improve the “curb appeal” of a building without adding a separate facade, many brands now offer Architectural CMU:

- Split-Face Block: These have a rough, stone-like texture created by “splitting” a double-sized block.

- Burnished or Ground-Face: These blocks are polished until the aggregates (the stones inside) are visible, creating a look similar to terrazzo or granite.

- Slump Block: These are removed from the mold while the concrete is still slightly wet, causing them to “slump” and look like handmade adobe.

3. Specialized Structural Shapes

Sash Blocks:

Feature a vertical slot to hold window frames.

Lintel or Bond Beam Blocks:

U-shaped blocks that hold horizontal rebar and grout to span over door or window openings.

CMU vs. Cinder Block: What is the Real Difference?

It is time to clear up the confusion once and for all. While people often use the terms interchangeably, they are technically different products.

- Cinder Blocks: These were common in the mid-20th century. They used “cinders” (fly ash or coal clinkers) as the aggregate. They were light but lacked high compressive strength.

- Concrete Blocks (CMU): These use stone, gravel, and sand as aggregate. They are significantly stronger, more weather-resistant, and are the only type approved for modern structural masonry under most building codes.

The Benefits of Building with CMU

As a brand committed to quality, we highlight these four pillars of Concrete Masonry Unit construction:

Superior Fire Resistance

CMU walls are non-combustible. Depending on the thickness and the type of aggregate used, a standard wall can provide a 2-hour to 4-hour fire rating. This makes them the go-to choice for stairwells, elevator shafts, and firewalls in commercial buildings.

Incredible Durability and Resilience

Unlike wood, concrete masonry does not rot, warp, or attract termites. It is also highly resistant to mold and mildew, which is critical for basement foundations and damp climates. In regions prone to hurricanes or tornadoes, reinforced CMU provides exceptional protection against high winds and flying debris.

High Thermal Mass and Energy Efficiency

While a single block has a low R-value (insulation value), its thermal mass is high. This means it absorbs heat during the day and releases it slowly at night. When combined with modern foam insulation, CMU buildings maintain steady internal temperatures, lowering heating and cooling costs.

Sound Insulation (STC Ratings)

Because of their density, Concrete Masonry Units are excellent at blocking noise. This is why they are frequently used in schools, hospitals, and multi-family housing units to ensure privacy and a quiet environment.

Critical Installation Components: Bond Beams & Moisture Control

To truly build like a pro, you must account for movement and water:

- Bond Beams: These are horizontal reinforced sections of the wall. They act as “belts” to hold the building together against lateral forces (like wind or earth pressure).

- Control Joints: Strategically placed vertical gaps filled with sealant that allow the wall to expand and contract without cracking.

- Flashings and Weep Holes: Essential in “Single-Wythe” (one-layer) walls to ensure any water that penetrates the block can escape through the bottom rather than rotting the interior.

How Much Does a CMU Wall Cost? (2026 Price Guide)

Estimating the cost of a CMU project involves two main factors: materials and labor.

- Block Price: A standard 8x8x16 hollow block typically costs between $2.10 and $3.50 depending on your location and the weight of the aggregate. Decorative or architectural blocks can cost $5.00 to $9.00 per unit.

- Installation Labor: Professional masons usually charge by the block or by the square foot. On average, expect to pay $12 to $18 per square foot for a professionally installed, reinforced wall.

- Total Project Estimate: For a standard retaining wall or foundation, a budget of $15 – $25 per square foot (including rebar, mortar, and grout) is a safe estimate for 2026.

2026 Trends: The Move Toward “Green” CMU

The construction industry is changing. We are now seeing a rise in Sustainable Masonry:

- Carbon-Sequestering Blocks: Some manufacturers are now injecting CO2 into the concrete during the curing process, permanently locking the gas inside the block.

- Recycled Aggregates: Using crushed glass or recycled concrete to reduce the need for mining new stone.

- Low-Carbon Cement: Replacing traditional Portland cement with volcanic ash or slag to reduce the carbon footprint of the CMU.

Actionable Tips for Your Next CMU Project

- Check for ASTM C90 Compliance: Always ensure your supplier provides blocks that meet the ASTM C90 standard for load-bearing units.

- Plan for Water Management: If building a retaining wall, always include weep holes and gravel backfill to prevent hydrostatic pressure from toppling the wall.

- Use Reinforcement: Never build a structural wall without vertical rebar and horizontal wire reinforcement. Concrete is strong in compression but needs steel for tension.

- Seal the Surface: Use a clear silane/siloxane sealer to prevent water from soaking into the block, which can cause efflorescence (white salty stains).

Summary:

Selecting the right CMU (Concrete Masonry Unit) is a foundational decision for the safety and efficiency of your structure. By following ASTM C90 compliance and using proper reinforcement, builders can prevent long-term maintenance issues like cracking and moisture damage.

Ultimately, high-quality masonry depends on the combination of strong materials and expert installation. Whether you are building a fire-resistant stairwell or a sustainable foundation, CMUs remain the most versatile tool in the 2026 construction market. Staying informed on these characteristics ensures your project is both structurally sound and cost-effective.