Maintaining the structural integrity of a masonry building requires more than just a passing glance at the facade. Over decades, the external mortar joints of a property bear the brunt of environmental stress, leading to gradual decay. When these joints fail, the building becomes vulnerable to water ingress, frost damage, and thermal loss. Understanding the relationship between masonry units and the mortar that binds them is the first step toward practical property preservation.

Professional Brickwork & Repointing is the corrective process of removing damaged mortar and replacing it with fresh, high-quality material. This practice is vital for both historic and contemporary structures, as it prevents moisture from penetrating the inner leaf of the wall. By addressing these issues early, property owners can avoid the high costs associated with significant structural failures. Modern restoration techniques now prioritize compatibility between old bricks and new mortar mixes to ensure long-term durability.

Current industry standards emphasize that the longevity of a wall depends heavily on the breathability of its joints. Utilizing the correct materials not only enhances the aesthetic appeal of a home but also improves its energy efficiency. As masonry restoration evolves, the focus has shifted toward using sustainable, lime-based solutions that mirror traditional craftsmanship. This comprehensive guide explores the essential techniques, costs, and benefits of maintaining high-quality masonry through expert intervention and meticulous care.

Quick Summary: Key Facts About Brickwork & Repointing

Brickwork & Repointing is the process of repairing the external mortar joints between bricks to ensure a building remains watertight and structurally sound.

- Primary Purpose: To prevent water ingress, stop spalling (brick crumbling), and enhance curb appeal.

- Best Materials: Natural Hydraulic Lime (NHL) for historic homes; Cement-lime mixes for modern builds.

- Average Lifespan: Quality repointing lasts 30–50 years, depending on exposure to elements.

- Warning Signs: Recessed mortar (deeper than 5mm), white salt stains (efflorescence), and damp internal walls.

- Ideal Temperature: Best performed between 5°C and 25°C to allow mortar to cure without cracking.

What is Brickwork & Repointing in Modern Construction?

In the realm of masonry, Brickwork & Repointing refers to the meticulous process of renewing the external portion of mortar joints. While the bricks themselves can last for centuries, the mortar acting as the “sacrificial” element typically has a shorter lifespan. As the mortar recedes due to wind and rain, it leaves the edges of the bricks exposed to “spalling,” where the brick faces begin to flake off. Repointing involves raking out the decayed material to a specific depth—usually twice the width of the joint—and packing in new mortar to create a weatherproof seal.

This process is critical because it manages how a building handles moisture. If the mortar is too hard, moisture gets trapped inside the brick; if it is too soft, it erodes too quickly. Achieving the perfect balance is the hallmark of a professional mason.

Key technical aspects include:

- Bedding Joints: These are the horizontal layers of mortar that carry the weight of the structure.

- Perpend Joints: The vertical gaps between bricks that require careful sealing to prevent leaks.

- Pointing Styles: Methods like weather-struck or flush pointing that affect how water sheds off the wall.

- Mortar Composition: The specific ratio of sand, lime, or cement used to create a compatible bond.

5 Critical Signs Your Property Needs Brickwork & Repointing

Recognizing when a building requires Brickwork & Repointing is essential for preventing internal dampness. The most apparent sign is visible gaps or “holidays” in the mortar lines where the material has fallen away. Another red flag is the presence of efflorescence, a white powdery salt that appears on the brick surface, indicating that water is moving through the masonry rather than evaporating from the joints. If the mortar is so soft that it can be scratched away with a fingernail, its structural bonding capacity has likely vanished.

Neglecting these warning signs can lead to “blown” brickwork, where the faces of the bricks crack during a freeze-thaw cycle. Homeowners should also look for interior signs, such as peeling wallpaper or damp patches on walls that align with external cracks. Early detection saves thousands in scaffolding and repair costs.

Common indicators include:

- Deep Erosion: Mortar recessed more than 5mm from the brick face, exposing the core.

- Cracked Joints: Hairline fractures that allow capillary water suction into the building’s interior.

- Loose Bricks: Masonry units that move or wobble when slight pressure is applied to them.

- Vegetation Growth: Moss, lichen, or weeds growing inside the moisture-rich, decayed mortar joints.

The Structural Benefits of Quality Brickwork & Repointing

Investing in professional Brickwork & Repointing offers significant structural advantages that extend far beyond mere aesthetics. By restoring the mortar joints, the load-bearing capacity of the wall is evenly distributed across the masonry units. This prevents localized pressure points that cause bricks to crack under the weight of the roof or upper floors. Furthermore, a sealed exterior acts as a primary barrier against “driving rain,” which is the leading cause of timber rot in floor joists that sit inside masonry pockets.

From a financial perspective, a well-maintained exterior significantly boosts property valuation and “curb appeal.” Prospective buyers and surveyors often check the condition of the pointing to gauge how well the home has been maintained. Additionally, Repointing improves the thermal performance of the building by eliminating drafts that enter through micro-fissures in the wall.

The core benefits include:

- Waterproofing: Effectively prevents rising and penetrating damp from reaching delicate interiors.

- Aesthetic Restoration: Returns the building to its original architectural glory and uniform color.

- Property Longevity: Extends the life of the brickwork by preventing total structural decay.

- Energy Efficiency: Reduces heat loss by sealing the building envelope against harsh elements.

Understanding Mortar Types for Brickwork & Repointing Projects

A common mistake in Brickwork & Repointing is the use of inappropriate mortar mixes, particularly on older buildings. Before the mid-20th century, most structures were built using lime-based mortars, which are flexible and “breathable.” If a modern, rigid Portland cement is used to repoint a historic lime-built wall, it can cause catastrophic damage. Because cement is more complex than old bricks, any movement in the building causes the bricks to crack rather than the mortar, leading to permanent masonry failure.

Selecting the right aggregate and binder is a science. Masons must consider the porosity of the brick and the local climate when mixing. For modern builds, a cement-lime-sand mix (Type N or O) is standard, while heritage projects require “hot lime” or hydraulic lime. This ensures that moisture can evaporate freely from the joint.

Essential materials include:

- Hydraulic Lime (NHL): Sets under water and offers excellent flexibility for natural building movement.

- Sharp Sand: Provides the structural “skeleton” and coarse texture of the mortar joint.

- Plasticizers: Additives that make the mortar easier to work into deep, narrow joints.

- Pigments: Natural oxides used to match the color of existing historic or decorative joints.

The Technical Step-by-Step Process of Brickwork & Repointing

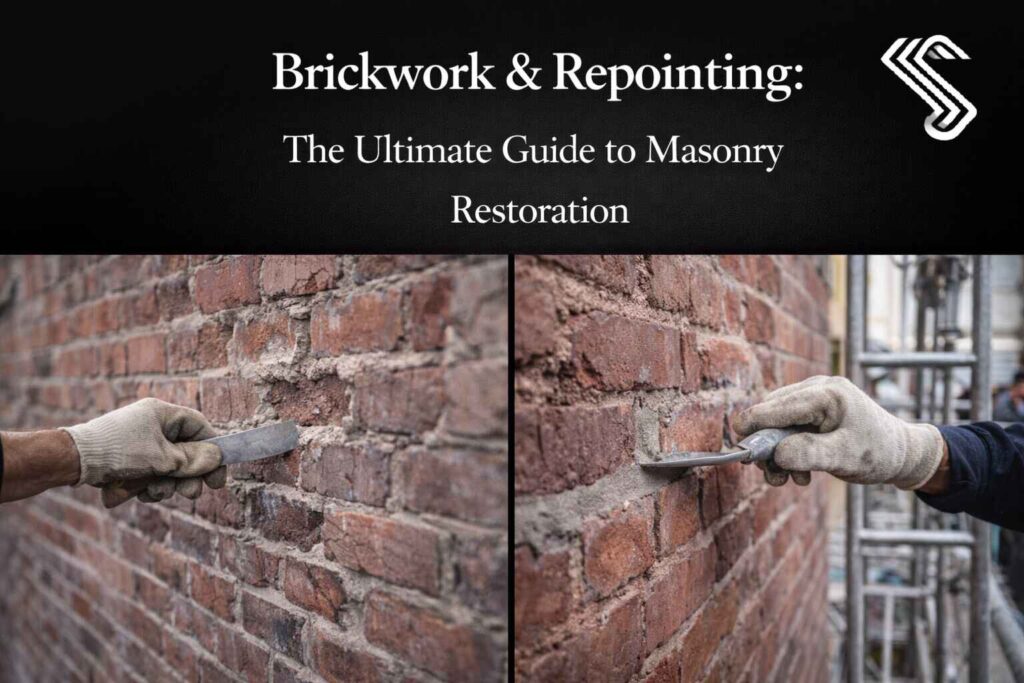

The execution of Brickwork & Repointing must follow a strict technical sequence to ensure a lasting bond. First, the old mortar must be “raked out” using specialized hand tools or dust-extracted power chisels. This must be done carefully to avoid “widening” the joints or scarring the bricks. Once the joints are cleared to a depth of roughly 20mm, they are cleaned with water or compressed air to remove dust, which acts as a “bond breaker.”

Next, the new mortar is applied in layers. Professionals use a “pointing trowel” and a “hawk” to firmly pack the material into the back of the joint, ensuring there are no air pockets. The finish—whether it is a “flush,” “recessed,” or “weather-struck” joint—is then applied as the mortar begins to stiffen. Proper “curing” is the final, vital step; the mortar must be kept moist and protected from direct sunlight or frost to prevent premature drying and cracking.

Key stages include:

- Site Preparation: Masking windows and setting up secure dust containment systems properly.

- Raking Out: Deep cleaning the joint to expose sound, solid, and clean material.

- Mixing: Achieving a “peanut butter” consistency for optimal wall adhesion and strength.

- Tooling: Shaping the joint to shed water effectively away from the porous brick face.

Why Professionals Outperform DIY in Brickwork & Repointing?

Many homeowners consider Brickwork & Repointing as a weekend DIY project, but the complexity is often underestimated. While repointing a low garden wall is manageable, working on the primary structure of a house requires specific skills and equipment. A professional mason understands how to color-match mortar, ensuring the repair is invisible. They also possess the rhythmic speed required to complete significant elevations before the mortar sets, preventing “cold joints” where new and old sections meet.

Hiring a professional also guarantees safety, especially when dealing with heights that require scaffolding. Mismanaged DIY attempts often result in “smearing,” where mortar is rubbed onto the face of the brick, causing permanent staining that requires expensive chemical cleaning to remove.

When deciding between the two, consider these factors:

- Skill Level: Matching historic styles requires years of apprenticeship and constant practice.

- Equipment: Industrial vacuum systems are needed to manage harmful silica dust effectively.

- Time Management: A professional crew can finish in days what might take a DIYer months.

- Warranty: Professionals often provide long-term guarantees on their workmanship and materials used.

Estimated Costs of Professional Brickwork & Repointing

The financial investment required for Brickwork & Repointing varies significantly based on the size of the property and the complexity of the masonry. Generally, contractors charge either by the square foot or by a daily labor rate. High-reach areas that require extensive scaffolding will naturally increase the budget. Additionally, if the previous owner used the wrong mortar, the cost to “rake out” hard cement is much higher than removing soft, sandy lime mortar.

On average, homeowners should expect to pay more for heritage restoration because the materials and labor-intensive hand-tooling are more specialized. However, this cost should be viewed as an investment in preventative maintenance. A properly repainted wall can last 50 years, whereas a poor job may fail in less than five. Budgeting should account for:

- Access Fees: Costs for scaffolding or cherry picker rentals for high, hard-to-reach walls.

- Waste Disposal: Removing and disposing of old mortar debris safely and legally.

- Material Costs: Specialized lime or custom-colored sands for a perfect architectural match.

- Cleaning: Post-pointing brick acid wash or steam cleaning to finalize the clean look.

Conclusion

Effective Brickwork & Repointing is the cornerstone of responsible property ownership. By maintaining the mortar joints, you are not just improving the appearance of your home; you are safeguarding its structural soul. Whether you are dealing with a historic cottage or a modern suburban home, the principles of choosing the right materials and using the correct techniques remain the same.

As we have explored, the transition from crumbling joints to a professionally restored facade involves understanding material science, environmental factors, and meticulous craftsmanship. While the initial cost may seem significant, the long-term savings in energy bills and structural repairs make it one of the most cost-effective home improvements available. Ensure your masonry stands the test of time by prioritizing quality restoration today.