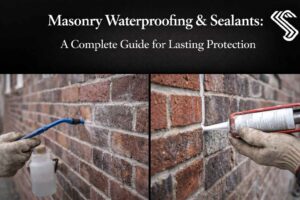

Water infiltration is one of the most common causes of structural deterioration in residential and commercial buildings. Waterproofing systems and construction sealants play a critical role in protecting building envelopes from moisture penetration, material degradation, and interior damage. When applied correctly, these systems help extend the lifespan of masonry, concrete, and exterior assemblies.

This article explains how waterproofing and sealants function, where they are applied, and why they are essential for long-term building performance.

What Is Waterproofing in Building Construction?

Waterproofing refers to the process of applying protective materials or systems that prevent water from entering structural components. These systems are designed to block moisture at vulnerable points such as foundations, walls, joints, and roof interfaces.

Unlike surface-level coatings, professional waterproofing solutions address both visible and hidden pathways that allow water intrusion. Effective waterproofing reduces the risk of corrosion, mold growth, freeze-thaw damage, and interior leaks.

The Role of Sealants in Moisture Control

Sealants are flexible materials used to close gaps, joints, and cracks in building assemblies. They accommodate movement caused by thermal expansion, structural settling, and vibration while maintaining a watertight seal.

Typical applications include window perimeters, expansion joints, masonry joints, control joints, and transitions between different building materials. Sealants work alongside waterproofing membranes to provide continuous moisture protection.

Common Areas That Require Waterproofing and Sealants

Water intrusion often begins at predictable locations within a structure. Identifying and treating these areas is essential for effective moisture control.

Key areas include:

- Foundation walls and below-grade structures

- Exterior masonry and concrete walls

- Window and door openings

- Expansion and control joints

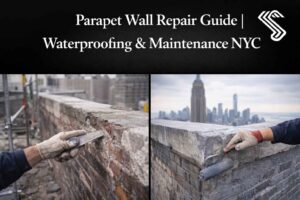

- Roof-to-wall and parapet transitions

- Balconies, terraces, and horizontal surfaces

Protecting these zones reduces long-term maintenance costs and structural risk.

Types of Waterproofing Systems Used in Construction

Different building conditions require different waterproofing approaches. Each system is selected based on exposure, substrate type, and environmental conditions.

Standard waterproofing systems include:

- Liquid-applied waterproof coatings

- Sheet membrane systems

- Cementitious waterproofing

- Elastomeric wall coatings

- Below-grade foundation membranes

Each system provides varying levels of flexibility, vapor permeability, and durability.

Types of Sealants Used in Exterior Applications

Sealant selection depends on joint movement, exposure to UV light, and compatibility with surrounding materials.

Common sealant types include:

- Polyurethane sealants

- Silicone sealants

- Hybrid elastomeric sealants

- Acrylic sealants (limited exterior use)

High-performance sealants maintain adhesion and elasticity over time, even in harsh weather conditions.

How Waterproofing Prevents Structural Damage?

Moisture penetration can weaken structural components over time. In masonry and concrete structures, trapped moisture leads to spalling, cracking, and reinforcement corrosion.

Waterproofing systems reduce:

- Freeze-thaw expansion damage

- Efflorescence and surface staining

- Interior leaks and damp conditions

- Mold and mildew growth

- Long-term material deterioration

Preventive waterproofing protects both structural integrity and occupant health.

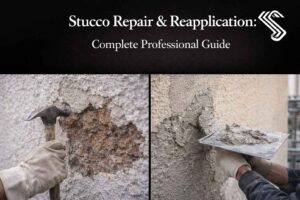

Importance of Surface Preparation and Application

The performance of waterproofing and sealants depends heavily on surface preparation. Contaminants such as dirt, salts, and deteriorated materials must be removed before application.

Proper preparation ensures:

- Strong adhesion

- Continuous moisture barriers

- Longer service life

- Reduced need for early repairs

Incorrect application is one of the leading causes of waterproofing failure.

Maintenance and Inspection of Waterproofing Systems

Waterproofing and sealants are not permanent solutions without maintenance. Regular inspections help identify wear, joint failure, or coating degradation before leaks occur.

Routine maintenance includes:

- Visual inspections of joints and coatings

- Resealing deteriorated joints

- Cleaning drainage systems

- Addressing cracks promptly

Proactive maintenance significantly extends system effectiveness.

Waterproofing as a Preventive Building Strategy

Rather than reacting to leaks, waterproofing should be part of a long-term building maintenance plan. Preventive systems reduce emergency repairs and help maintain property value.

Buildings with effective waterproofing typically experience fewer structural issues and lower lifecycle repair costs.

Conclusion

Waterproofing and sealants are essential components of modern building protection. By preventing moisture intrusion, these systems preserve structural materials, improve durability, and support long-term building performance. Understanding how waterproofing and sealants function allows property owners and managers to make informed decisions that protect their assets over time.