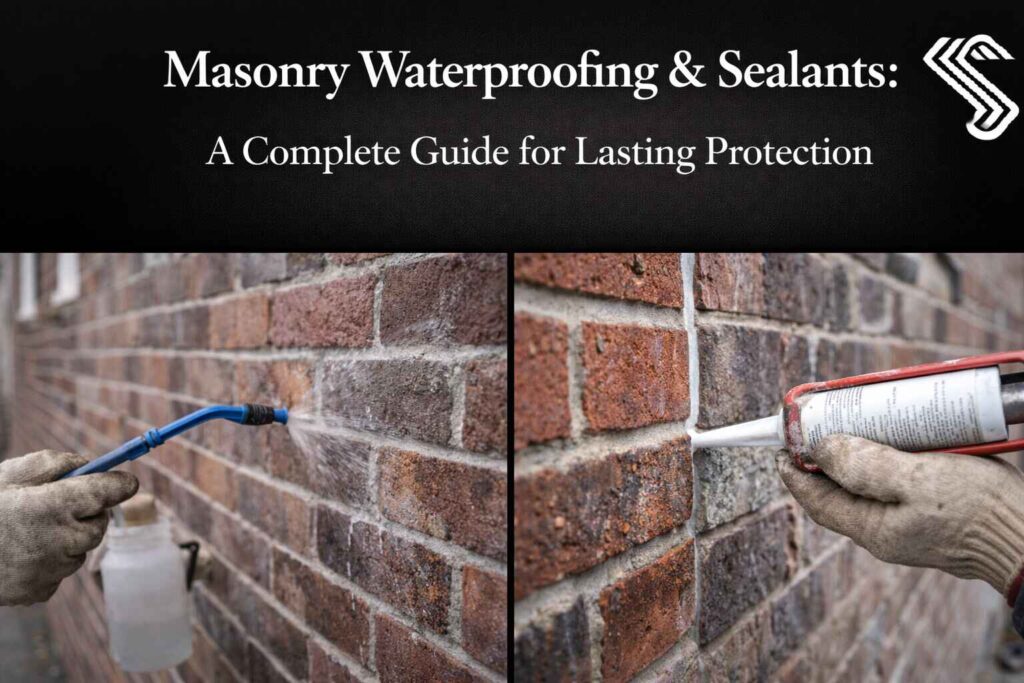

Masonry structures, including brick, stone, and concrete walls, are often exposed to harsh environmental conditions. Rain, humidity, and moisture seepage can silently damage the masonry over time. Masonry waterproofing & sealants serve as the first line of defense, preventing water infiltration that leads to cracks, mold growth, and structural weakening. Professionals and homeowners alike recognize the importance of applying the right sealants and coatings to extend the life of their masonry surfaces.

The effectiveness of masonry waterproofing & sealants depends on selecting the right product and applying it correctly. Liquid coatings, cementitious sealers, and silicone-based solutions each offer unique benefits. Understanding the properties of masonry surfaces and matching them with suitable sealants ensures proper water resistance, durability, and long-term protection against environmental wear.

Proper application and maintenance of masonry waterproofing & sealants can save significant repair costs. Regular inspections, timely reapplication, and attention to cracks or surface damage preserve both structural integrity and aesthetic appeal. This guide explores the types, processes, and best practices for protecting masonry effectively and maintaining a resilient, water-resistant building envelope.

What is Masonry Waterproofing & Sealants?

Masonry waterproofing & sealants are specialized protective solutions designed to prevent water infiltration in brick, stone, and concrete surfaces. These products form a barrier that restricts moisture while allowing masonry to breathe, preserving both structural integrity and appearance. Waterproof coatings penetrate porous surfaces, filling gaps and protecting against rain, humidity, and environmental contaminants.

Sealants, on the other hand, are flexible materials applied to joints, cracks, or surface areas prone to leakage. They maintain adhesion under expansion and contraction caused by temperature fluctuations. Typical materials include acrylics, silanes, siloxanes, and elastomeric compounds. Professionals often combine coatings and sealants for comprehensive protection, ensuring every exposed surface is safeguarded.

Using masonry waterproofing & sealants also improves energy efficiency by preventing damp-induced heat loss in buildings. They contribute to longevity by reducing maintenance requirements and minimizing costly repairs. Choosing the right sealant type and application method is critical for achieving durable, water-resistant masonry.

Why Masonry Waterproofing is Essential?

Water damage is a primary threat to masonry structures, often causing cracks, efflorescence, and spalling. Applying masonry waterproofing & sealants protects walls from water penetration, prolonging structural life and preserving aesthetics. Moisture can weaken mortar, erode bricks, and compromise concrete, leading to expensive repairs if left untreated.

Key benefits of effective waterproofing include:

- Structural protection: Prevents deterioration of bricks, stones, and concrete foundations.

- Mold and mildew prevention: Reduces health hazards and indoor air quality issues.

- Energy efficiency: Moisture-free walls maintain better insulation and reduce heating costs.

- Aesthetic preservation: Keeps masonry looking new and clean, free from water stains.

Professional application of masonry waterproofing & sealants ensures uniform coverage and long-lasting protection. By understanding the importance of water-resistant surfaces, homeowners and builders can proactively safeguard structures from environmental damage.

Types of Masonry Waterproofing & Sealants

There are multiple types of masonry waterproofing & sealants, each suited to specific surface conditions and environmental factors. Choosing the right type ensures optimal performance and longevity. The main categories include:

Liquid-Applied Coatings

- Elastomeric or acrylic-based paints

- Applied via brush, roller, or spray

- Form a continuous waterproof layer

- Flexible, allowing expansion and contraction

- Ideal for exterior walls and facades

Cementitious Coatings

- Cement-based waterproofing applied to foundations and basements

- Highly durable and cost-effective

- Provides a breathable layer preventing water penetration

- Resistant to negative and positive water pressure

Silicone-Based Sealants

- Penetrating sealers for brick and stone

- Water-repellent and breathable

- Preserves natural look and color of masonry

- Excellent for exterior surfaces exposed to frequent rainfall

Acrylic Sealants

- Flexible and protective coating for masonry joints and cracks

- UV-resistant, suitable for sunny climates

- Easy to apply and maintain

- Enhances long-term durability of walls

Selecting the appropriate masonry waterproofing & sealants depends on the substrate, environmental conditions, and desired protection level. Professionals often combine multiple types to achieve comprehensive coverage.

Step-by-Step Masonry Waterproofing Process

A systematic approach ensures that masonry waterproofing & sealants perform effectively. The following steps are essential for optimal results:

1. Surface Preparation

- Clean walls of dirt, debris, and old coatings

- Repair cracks, holes, and damaged mortar

- Ensure the surface is dry for proper adhesion

2. Selecting the Right Sealant

- Choose products based on masonry type (brick, stone, concrete)

- Consider weather exposure and water pressure

- Match sealant permeability with wall breathability

3. Application Method

- Brush, roller, or spray depending on coating type

- Apply in even, thin layers for complete coverage

- Follow manufacturer instructions for drying times

4. Curing and Inspection

- Allow proper curing to enhance performance

- Inspect for missed areas or uneven application

- Reapply where necessary for full protection

5. Maintenance and Reapplication

- Schedule inspections every 1–2 years

- Clean and remove dirt or moss from surfaces

- Reapply sealants or coatings as needed to maintain water resistance

Following this process ensures that masonry surfaces remain durable, water-resistant, and visually appealing, providing long-term structural protection.

Maintenance Tips for Long-Lasting Masonry Waterproofing & Sealants

Proper maintenance is crucial to ensure that masonry waterproofing & sealants continue to protect walls effectively over time. Regular inspection and care extend the life of the sealants and prevent water-related damage before it becomes costly.

Key maintenance practices include:

- Routine inspections: Check for cracks, peeling coatings, or signs of water ingress every 6–12 months.

- Cleaning surfaces: Remove dirt, moss, algae, or salt deposits that can reduce sealant effectiveness.

- Reapplication of sealants: Depending on the product type, most coatings require reapplication every 2–5 years to maintain full protection.

- Addressing damage promptly: Repair any minor cracks or damaged joints immediately to prevent water penetration.

- Monitor environmental impact: Seasonal changes and exposure to heavy rain or sun may reduce sealant lifespan.

By following these steps, property owners can maximize the durability and performance of masonry waterproofing & sealants, ensuring walls remain resilient and visually appealing.

Environmental & Safety Considerations in Masonry Waterproofing

Selecting the right masonry waterproofing & sealants involves not only performance but also environmental and safety concerns. Modern sealants offer sustainable options that reduce environmental impact without compromising protection.

Key points include:

- Eco-friendly sealants: Low-VOC and water-based coatings are safe for both users and the environment.

- Proper handling: Wear gloves and protective clothing during application to avoid skin irritation or inhalation hazards.

- Compliance with building codes: Ensure products meet local standards for waterproofing and fire safety.

- Disposal of materials: Avoid improper disposal of leftover sealants; follow manufacturer guidelines for recycling or safe waste management.

- Durable, long-lasting protection: Choosing high-quality sealants reduces frequent reapplication, minimizing environmental impact.

Integrating environmental and safety practices alongside masonry waterproofing & sealants ensures long-term protection while maintaining sustainability and health standards.

Best Materials & Products for Masonry Waterproofing & Sealants

The effectiveness of masonry waterproofing & sealants largely depends on selecting the right products. High-quality materials ensure durability, water resistance, and ease of application.

Some of the best options include:

- Silane & Siloxane Sealers: Penetrate deep into brick or stone surfaces, offering breathable, long-lasting water repellency.

- Elastomeric Coatings: Flexible, UV-resistant paints ideal for exterior walls, preventing cracking and water penetration.

- Cementitious Waterproofing: Cement-based coatings suitable for foundations, basements, and walls exposed to constant moisture.

- Acrylic Sealants: Excellent for joints and cracks, UV-resistant, and easy to apply for both professionals and DIY enthusiasts.

- Combination Approaches: For challenging conditions, using a liquid coating on walls plus silicone-based sealant on joints ensures maximum protection.

Selecting products based on masonry type, exposure, and environmental factors is key to achieving long-term water-resistant masonry protection.

Common Challenges in Masonry Waterproofing & How to Overcome Them

Even with quality products, applying masonry waterproofing & sealants can face practical challenges that affect results. One frequent issue is uneven absorption due to inconsistent masonry porosity, which can leave weak spots. Harsh weather conditions, such as heavy rain during application, can also compromise adhesion. Improper surface preparation or selecting a sealant unsuitable for the masonry type often leads to peeling or early wear.

Practical solutions include:

- Conducting moisture tests before application to identify problem areas.

- Using primer layers to improve sealant bonding on uneven surfaces.

- Timing application during dry and mild weather conditions.

- Consulting product guidelines to match sealants with masonry type.

- Incorporating joint reinforcement for high-stress areas prone to cracks.

These approaches minimize common failures, ensuring the waterproofing lasts longer and provides full protection.

Cost and ROI of Masonry Waterproofing & Sealants

Investing in masonry waterproofing & sealants is not just an expense—it’s a preventive strategy that saves money in the long term. Costs vary depending on materials, wall size, and whether professionals or DIY methods are used. High-quality sealants may have higher upfront prices but reduce maintenance frequency and prevent expensive water damage repairs.

Key considerations for ROI include:

- Longevity benefits: Durable coatings minimize repeated applications.

- Damage prevention: Protects against structural repairs, mold remediation, and efflorescence treatment.

- Property value impact: Well-maintained masonry boosts resale appeal.

- Energy efficiency: Dry, sealed walls improve insulation and reduce utility bills.

- Scalable solutions: Investing in partial applications, such as foundations or critical walls, can deliver incremental returns before full coverage.

Understanding both costs and long-term value allows property owners to make informed decisions and optimize investment outcomes.

Proactive Maintenance Strategies for Masonry Waterproofing & Sealants

Effective masonry waterproofing & sealants requires a proactive maintenance approach rather than reactive repairs. Scheduling consistent checks helps detect minor issues before they escalate into structural damage. Environmental factors like temperature fluctuations, UV exposure, and rain cycles impact sealant performance and must be considered in maintenance planning.

Proactive strategies include:

- Seasonal inspections: Assess walls after winter or rainy seasons for water stains or erosion.

- Targeted cleaning: Use gentle methods to remove algae, dirt, or pollutants that degrade coatings.

- Localized touch-ups: Focus on high-risk areas such as corners, joints, and exposed surfaces.

- Documentation: Keep a maintenance log to track application dates, product types, and observed issues.

- Predictive reapplication: Reapply sealants before visible wear appears, extending overall service life.

These steps not only preserve the structural integrity of masonry but also maintain its aesthetic appeal, ensuring long-term protection.

Conclusion

Effective masonry waterproofing & sealants are essential for protecting structures from water damage, preserving aesthetics, and extending the life of walls. Choosing the right products, following proper application steps, and maintaining regular inspections ensure walls remain water-resistant, durable, and visually appealing.

By integrating high-quality sealants, eco-friendly coatings, and systematic maintenance, property owners can confidently safeguard masonry surfaces. Implementing these strategies not only prevents structural damage but also reduces long-term repair costs, making masonry waterproofing & sealants a vital investment for any property.